Are you unclear about the environmental impact of your product, packaging or service? Is it harmful to the environment or to your customers? Or has your product environmental benefits over your competition?

With almost 50% of all emissions embodied in materials, it is important to gain transparency of the environmental impact associated with your products. Your customers are increasingly likely to want to measure the impact of the products and services they procure from you as they will appear in their Scope 3 GHG emissions.

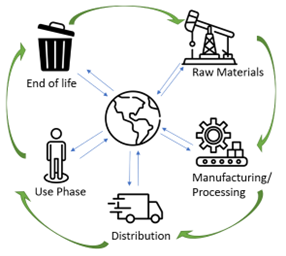

Improving the sustainability of products and services will likely be different for every business. The approach requires holistic overview & analytical accuracy of the end to end process… from ‘Cradle to Grave’. Implementing a life cycle assessment (LCA), will systematically record the entire life cycle of a product of service. This is done by capturing and analysing its impact on the environment typically in terms of GHG emissions. However, other environmental impacts may also be measured.

With almost 50% of all emissions are embodied in materials, it is important to gain transparency of your environmental impacts associated with your products and services.

With over 25 years industry experience in the LCA, Clearstream Solutions and its team of expert assessors manage and conduct LCA’s, to identify the right actions and approach for your business by measuring the environmental impact assessments of your products and services. As a result, this process can be used to assess alternatives and identify the appropriate actions required to reduce your carbon footprint.

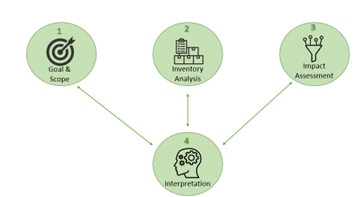

An LCA is broken down into four main steps: goal and scope, inventory analysis, impact assessment and interpretation. By doing a LCA, this process will assist in purposefully locating and then implementing sustainable processes optimisations.

Goal and scope: this is the step where the aim and boundaries of the project and defined. Here the focus area is decided, and how in depth of an analysis done is chosen.

Inventory analysis: the data collection for all inputs and outputs.

Impact assessment: converting the data into impacts

Interpretation: arguably the most important step, this is where the impacts are quantified, evaluated and checked against the aim.

Coca Cola is widely considered the first to ever complete a life cycle assessment. Back in 1969. They wanted an all-inclusive study of their packaging, accounting for energy, waste and resources. The large majority of LCAs from the early days focused on packaging. For instance, LCA was used for its ability to assess emissions, energy usage, waste and resources.

Coca Cola is widely considered the first to ever complete a life cycle assessment. Back in 1969. They wanted an all-inclusive study of their packaging, accounting for energy, waste and resources. The large majority of LCAs from the early days focused on packaging. For instance, LCA was used for its ability to assess emissions, energy usage, waste and resources.

Why use LCA?

Life cycle assessment helps guide you to the best solution. Firstly, It allows you to review the overall picture before making a decision. Up to 80% of a product’s environmental impact can be determined during the design phase. Secondly, Using LCA, it can highlight areas with high impacts in the current process, and areas the design could be optimised. Moreover, LCA as a tool during design can lead to less prototyping and secure resources to the ideal places. In conclusion encouraging more creative and innovative solutions. It can be linked to increases in circularity and help not only reduce waste but allow comparisons between sourcing. The process can cover raw material extraction, transportation, all manufacturing processes and stages, use-phase, and the end-of-life possibilities. All inputs are broken into the various single components for the product and shows the outputs that happen from this. An LCA not only accounts for the carbon footprint but other environmental impacts like water acidification or human health impacts.

LCA is a reporting tool, with benchmarking and analysis the bases for the process. It can however be used to alter designs and encourage broader thinking during this stage. Having a visual representation of the impacts, with ease for comparing different sources, allows the design teams to pick the best option for their product for both people and the planet.

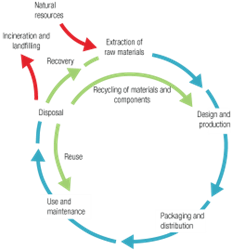

How does LCA tie in with the circular economy?

LCA can help strengthen the circular economy. It is a robust tool that measures the environmental impact and can model how utilising the circular economy will improve the impacts of life extension, reuse, harvesting, repair, and disposal.

In addition, removing the disposal section will show the limitations and highlight the alternatives. Using Life Cycle Analysis and Circular Economy thinking will help implement circularity throughout the business. Using and embracing LCA can lead to innovative steps and continued growth.

LCA is a way of thinking that includes the economic, social and environmental consequences of a product or process over its entire life cycle – UENP Life Cycle Initiative.

Using Life Cycle Analysis during the design process an aid in decision making. Some advantages to LCA:

- Shows the consequences of each stage of the products life

- Update and innovate without prototyping

- Shows how small changes can affect the overall impact

- Can gather information on not only land impacts, but water, air and human affects too

- Aid carbon foot printing

- Make more informed decisions

- Compare different products to find best solution

- Can help identify improvement areas

- Can include material extraction, manufacturing processes, use, end of life solutions

- CE & LCA – interconnected

- How recovery of waste will remove emissions

- Planning strategies for future projects

- Design out pollution

Aoife Green is a Product Sustainability Associate at Clearstream Solutions. Aoife graduated from Dublin City University with a MEng in Sustainable Energy & Systems and a bachelor’s in Mechanical & Manufacturing Engineering.